0 saved

0 saved

19.1K views

19.1K views

Perhaps you want to implement Agile Methodology but want an alternative to Scrum? Or maybe you're just interested in a flexible approach to boost personal productivity? Either way, Kanban is worth a look.

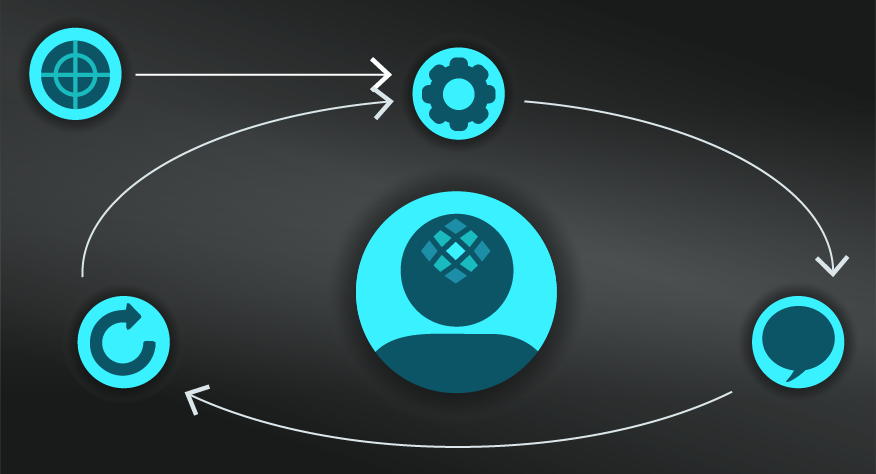

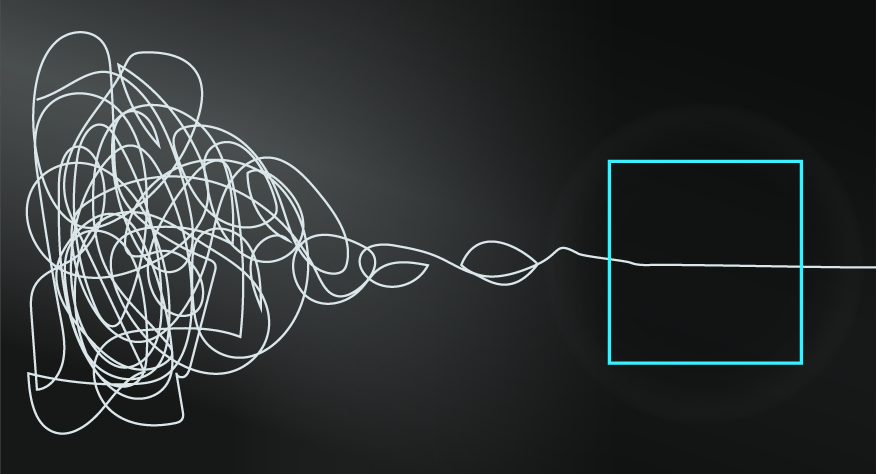

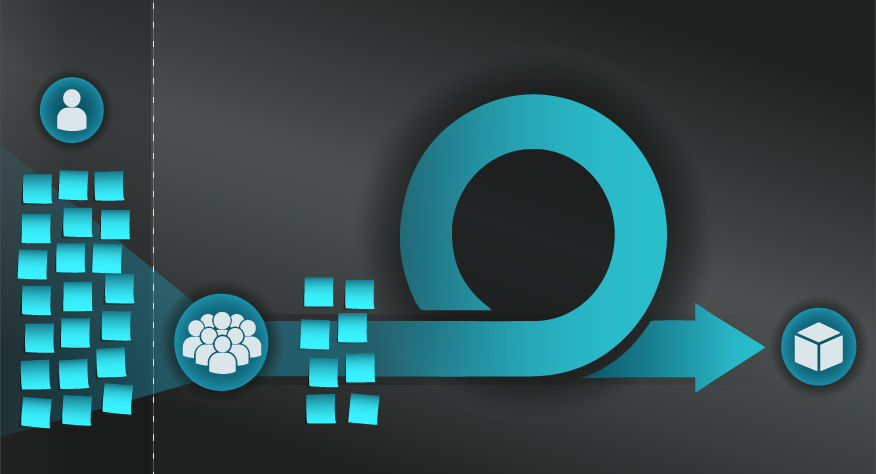

Kanban is a visual approach within Agile Methodology that helps to limit work in progress and overcome bottlenecks by transparently managing a continuous workflow.

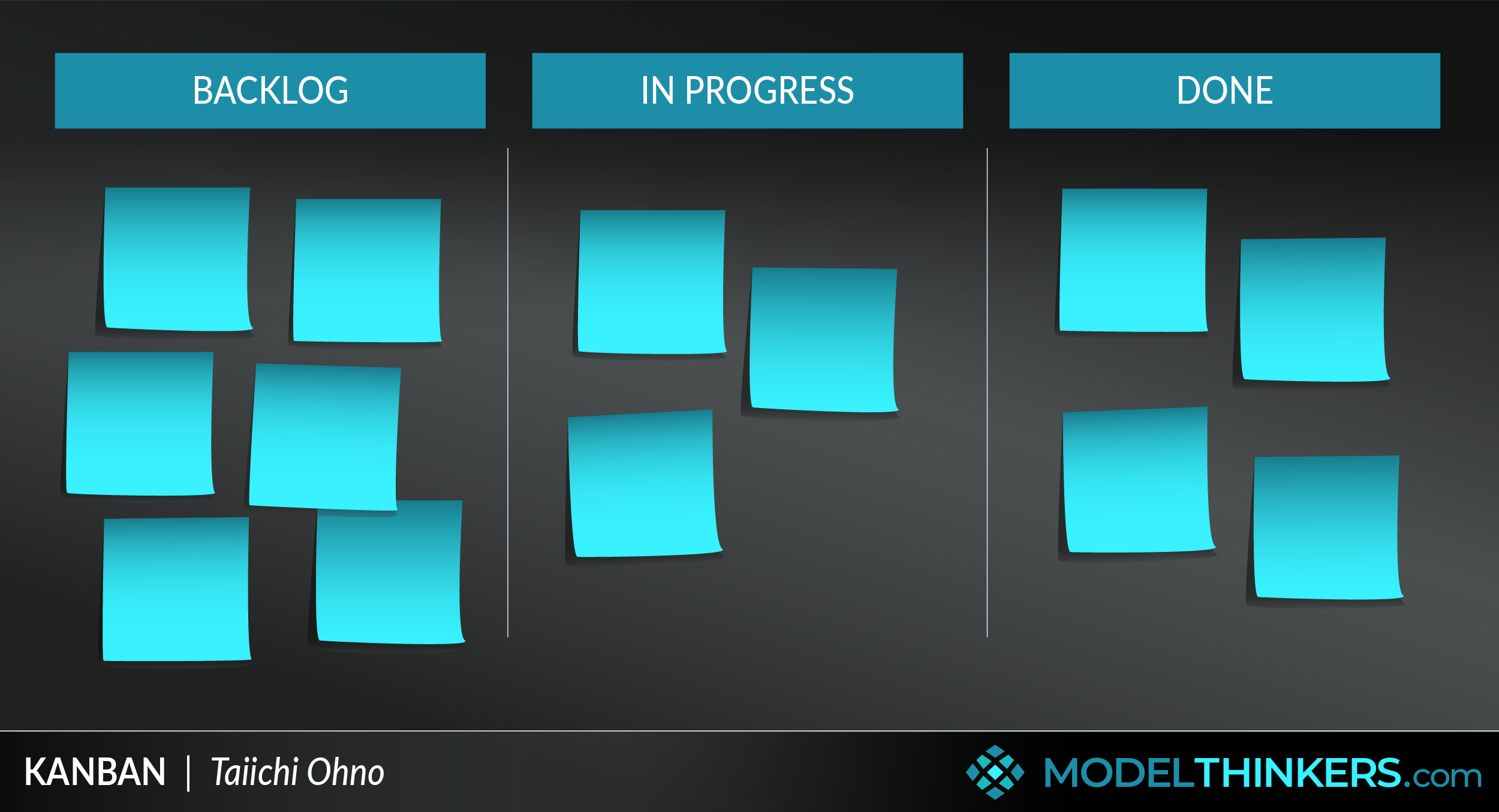

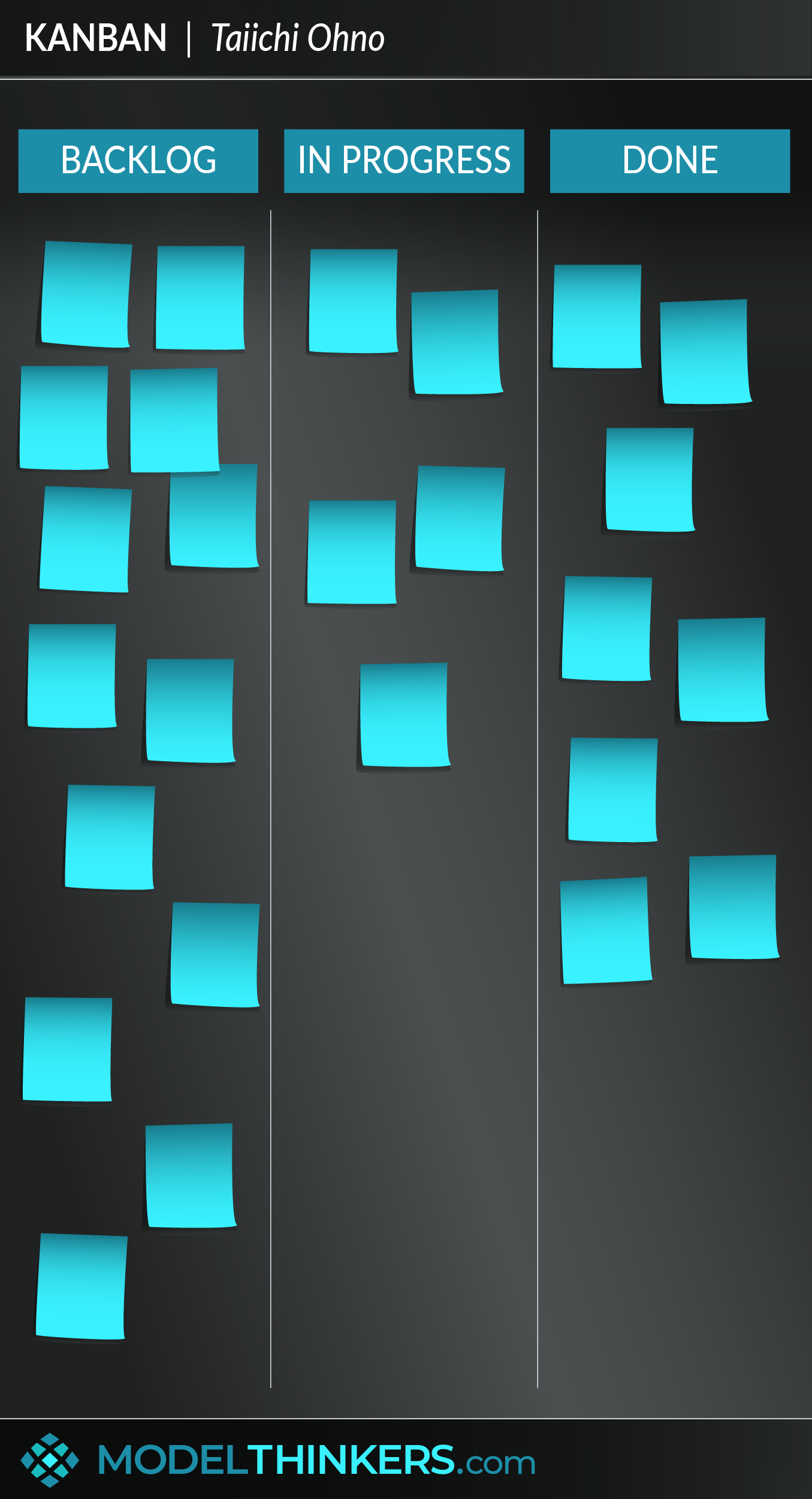

KANBAN BOARDS.

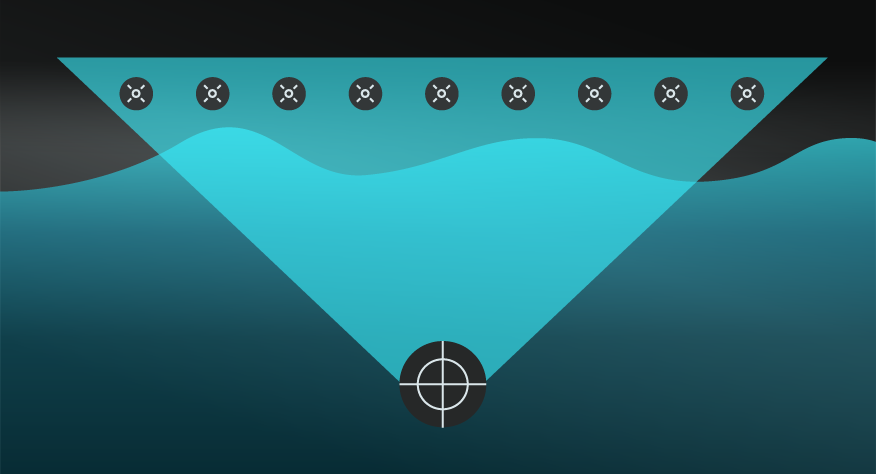

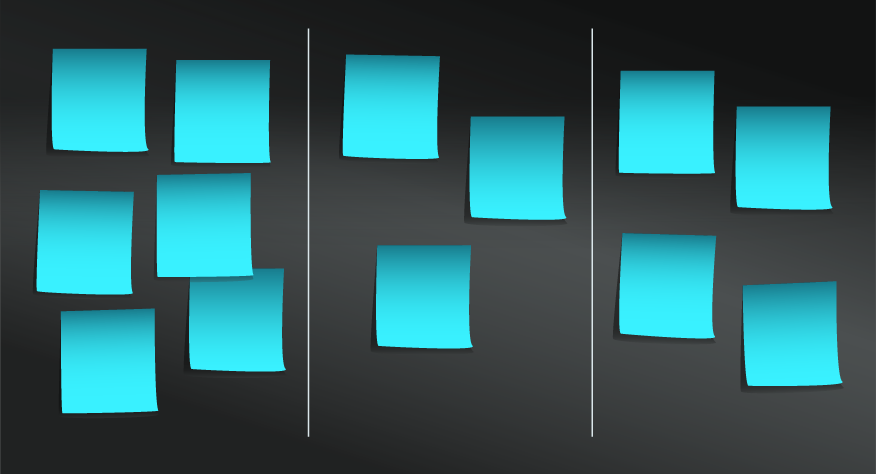

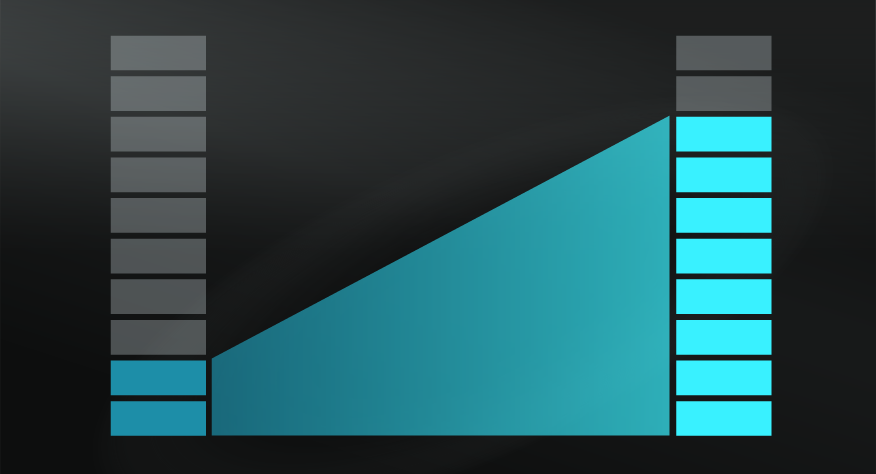

The method uses virtual or physical Kanban boards to visualise an entire project workflow and cards to represent work. At its simplest, such kanban boards consist of three columns: to-do, doing and done. However, in reality, they tend to include additional columns such as backlog, requested, planned, prioritised, blocked, tested and so on.

Cards, which represent work, are organised across these columns, moving from left to right over the board — beginning in the backlog, a list of possible activities and ideas that could add value to the project, shifting to work in progress, and finally marked as ‘done’.

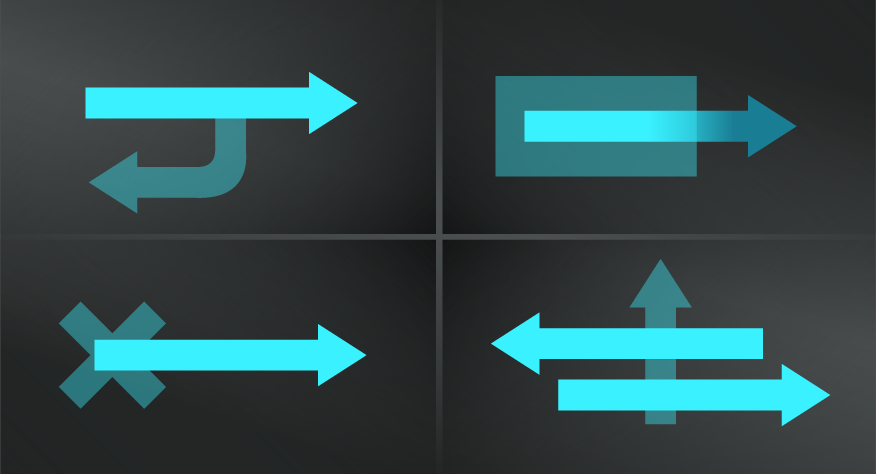

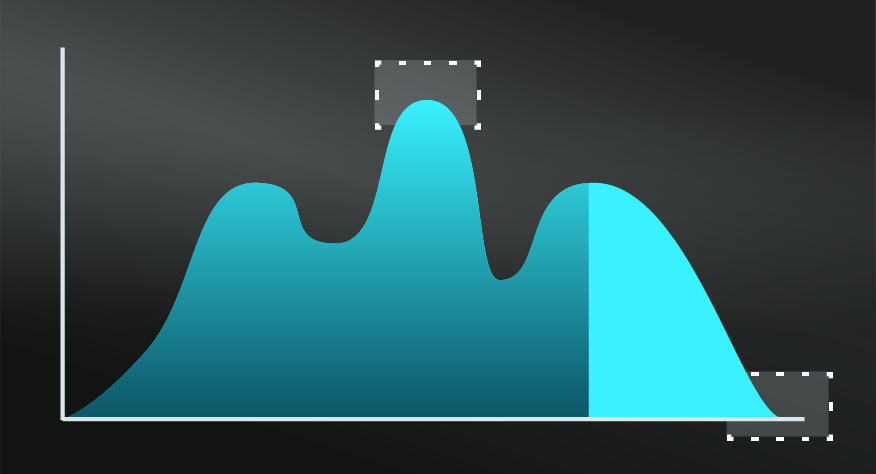

Kanban helps to manage capacity since cards can only progress when the next column has bandwidth or space for them. It also encourages high visibility over the work to better identify bottlenecks and opportunities to collaborate. Kanban is generally implemented as a continuous process that is incremental but, unlike Scrum, is not iterative.

THREE PRINCIPLES.

Kanban embraces three key principles:

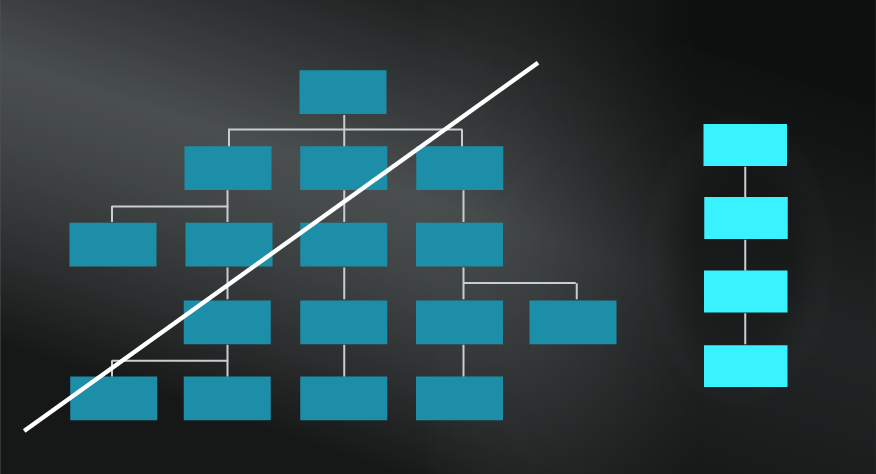

- Start with what you do now, with a pragmatic approach to the current state.

- Agree to pursue improvement through evolutionary change.

- Encourage acts of leadership at every level, challenging a hierarchical approach.

APPLICATIONS.

Consider using Kanban instead of Scrum to better manage a large and unpredictable flow of incoming requests and get started with less training. That said, it's also a powerful approach to combine with Scrum. See the In Practice section below for examples of specific industry Kanban boards.

On a personal level, consider using Kanban to organise yourself — having experimented with about two dozen different productivity apps and methodologies, I swear by it.

- Visualise your workflow as a kanban board.

Use software or a physical wall to establish a kanban board. Choose columns that represent the workflow from left to right. Consider which columns are most useful and will add greater transparency in your context, with the basics being to-do, doing and done.

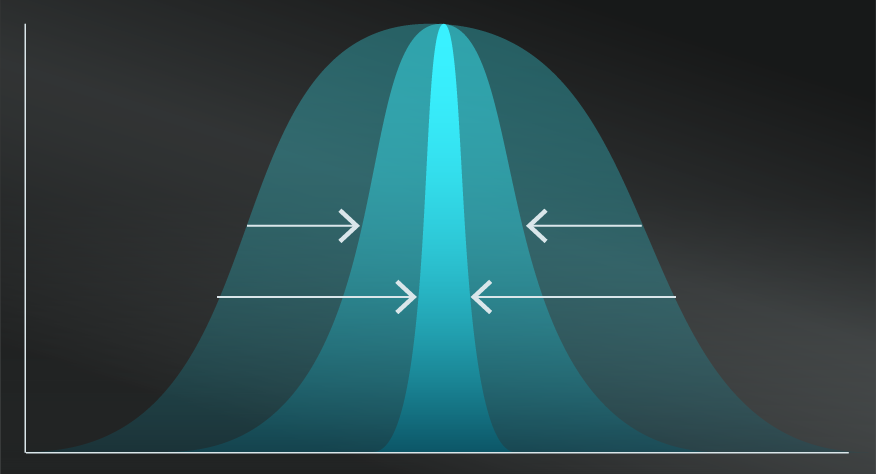

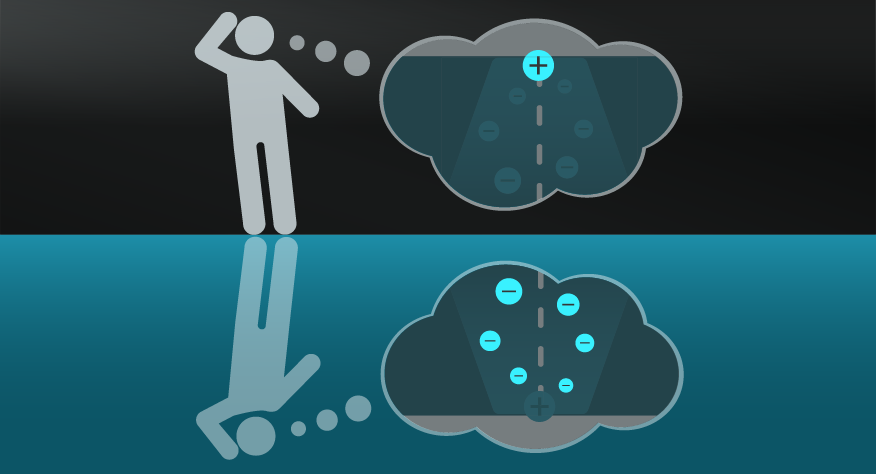

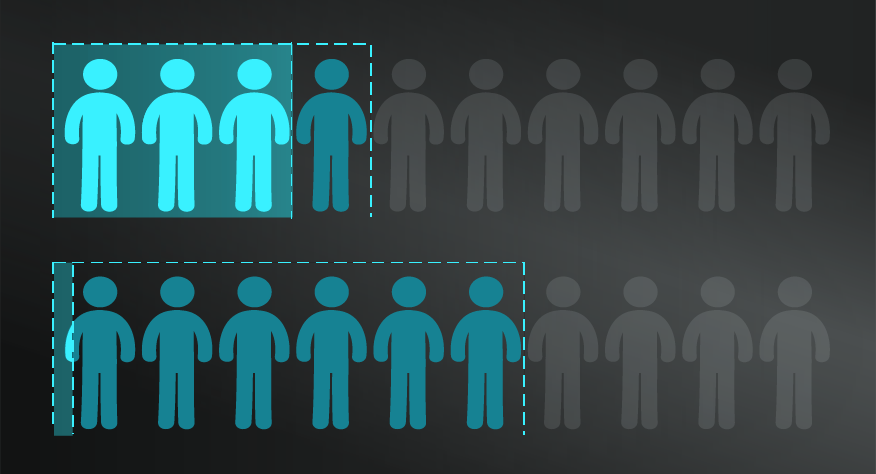

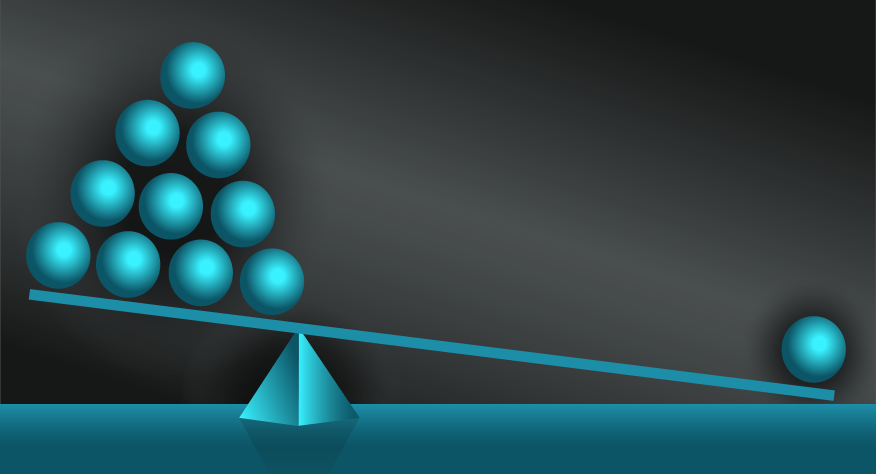

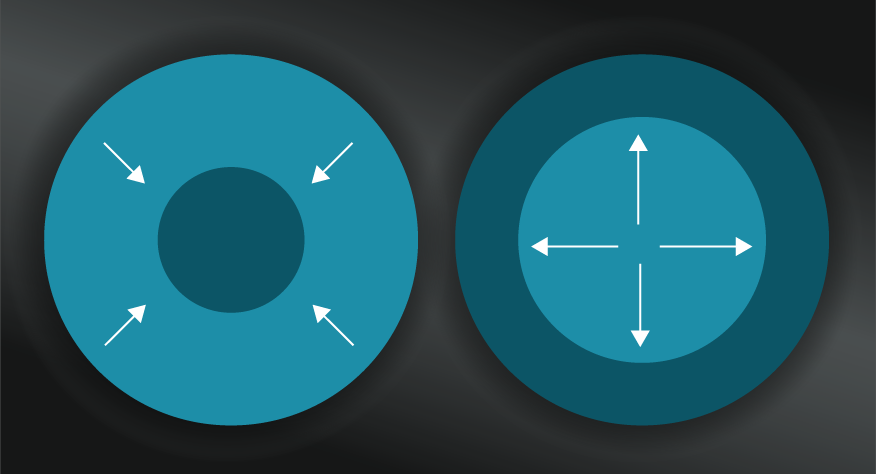

- Limit your work in progress

Establish capability limits for your work to support efficiency and sustainability. This involves identifying how many cards will be allowed within a column at any given time.

- Capture the work as kanban cards.

Every work item must be captured as a kanban card which might incorporate a title, description, possibly a picture, an owner, due date and comments. In digital kanban boards, these cards will evolve and be updated as they move through the workflow and the work is done. A card will often capture work that can be progressed over 1 to 2 days and might be generated by customer requests or team members alike.

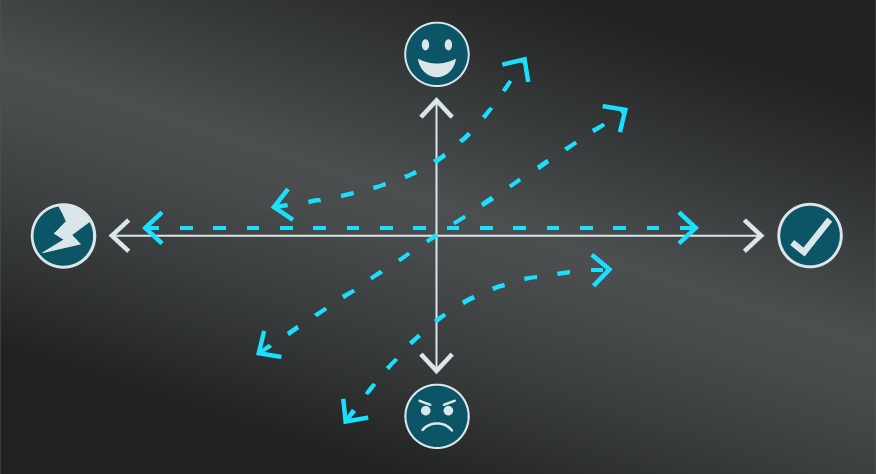

- Prioritise and progress cards.

The team and team members then continuously prioritise high-value cards from the backlog to pull into the workflow as space becomes available.

Kanbans are powerful tools to capture existing workflows and find improvements and efficiencies in them. They do however require a cultural shift to implement and might face resistance, particularly for the level of transparency they offer.

Beyond general resistance to change, other challenges arise when people see it as a one-way process when in reality their process might jump back and forth unpredictably between stages.

Toyota and kanban based production scheduling.

Toyota develop kanban as part of its lean manufacturing approach to provide just-in-time parts as part of the Toyota Production System. Parts would be delivered as spaces opened for them, reducing the need for storage. Toyota have six rules for their kanban implementation:

- Never pass on defective products

- Take only what is needed

- Produce the exact quantity required

- Level the production

- Fine-tune production

- Stabilize and rationalise the process

Industry kanban boards.

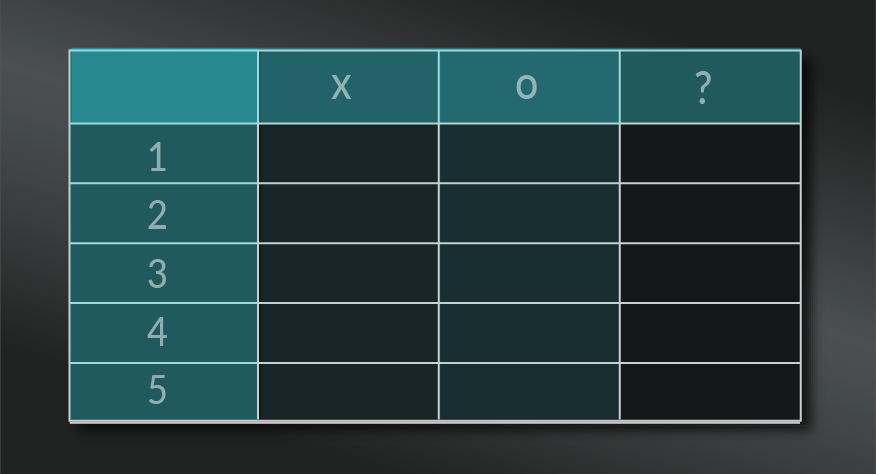

Columns that might be included for various industries and projects reflect relevant workflows, for example:

- Sales: lead; contact made; meeting booked; needs identified; proposal sent; pitch; won; lost; blocked.

- Recruitment: long list; interview 1; short list; offer sent; hired.

- Procurement: engaged; requested quote; waiting; raise PO; completed.

Kanban, like scrum, is part of agile methodology and can be used to achieve greater efficiencies and productivity for teams and individuals in a range of fields.

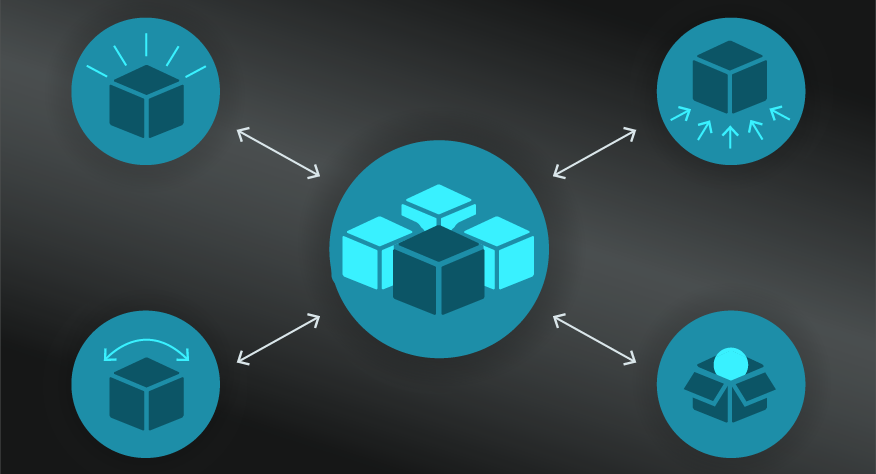

Use the following examples of connected and complementary models to weave kanban into your broader latticework of mental models. Alternatively, discover your own connections by exploring the category list above.

Connected models:

- Agile methodology: which frames kanban in broader techniques and processes.

- Scrum: an alternative agile approach that is often implemented in conjunction with elements of kanban.

- Lean thinking: particularly focusing on process optimisation supported by kanban.

- Black box thinking: the transparency offered by kanban could be part of an open-loop system with the inclusion of feedback loops.

- Divide and conquer: kanban relies on breaking work down into manageable kanban cards.

Complementary models:

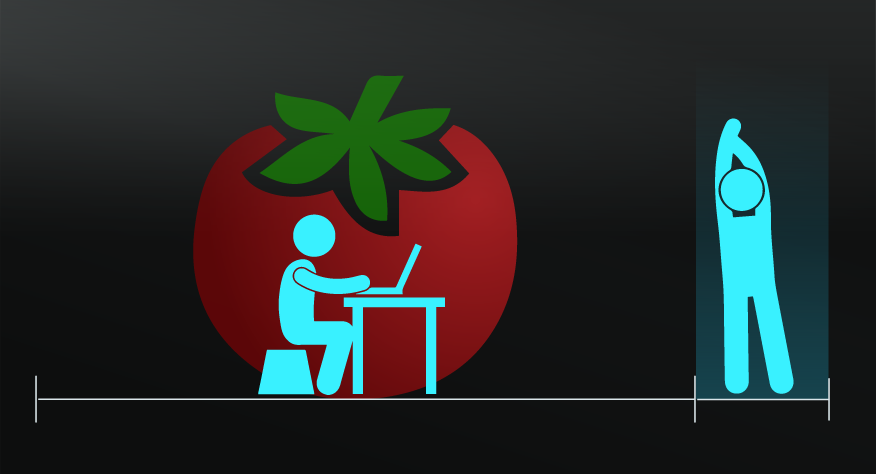

- Parkinson’s law: when applied here, this law could argue that the work of kanban cards will tend to extend to the basic unit of time they are built on.

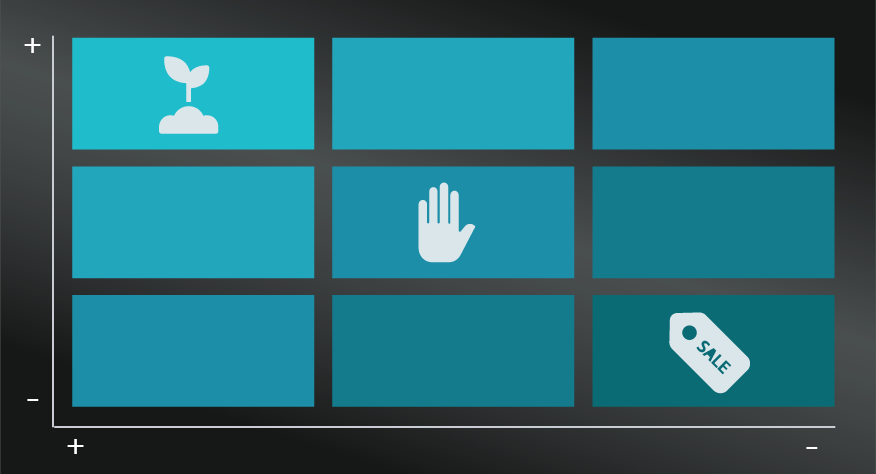

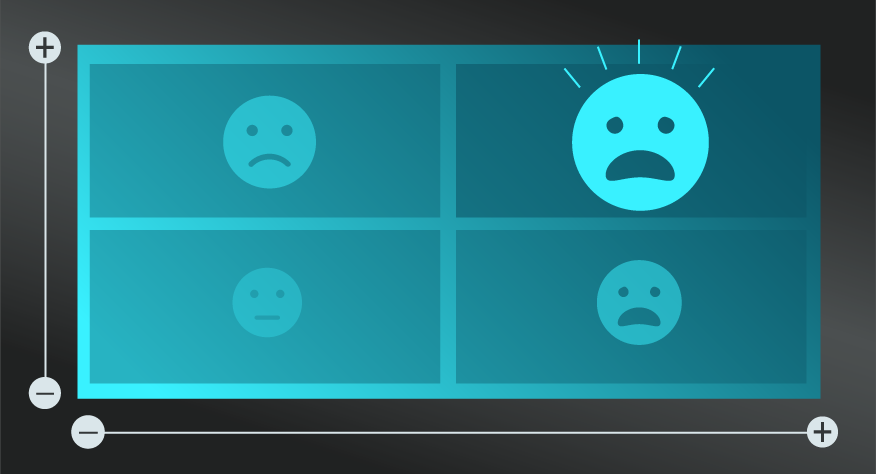

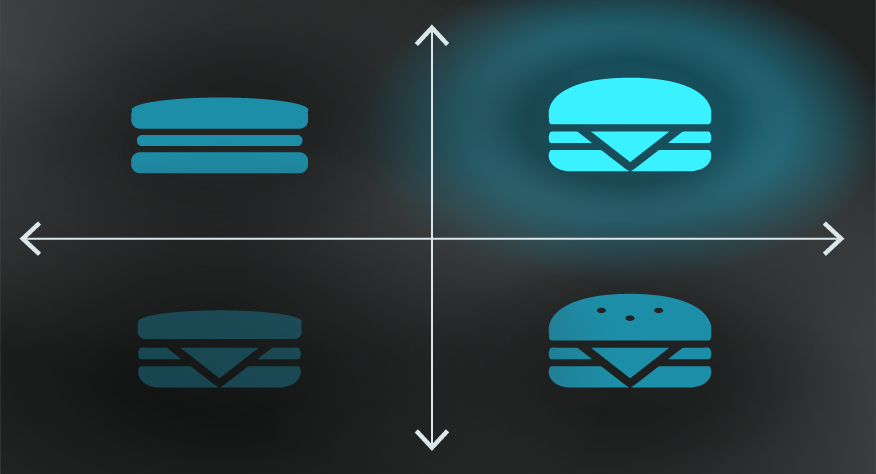

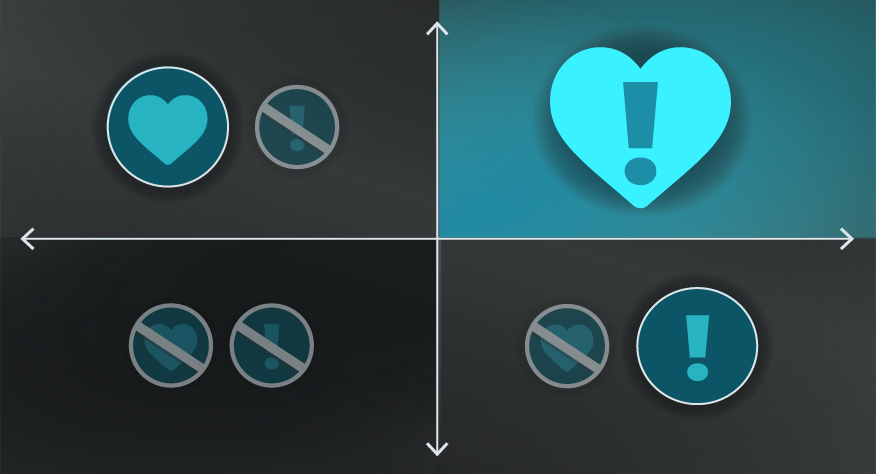

- Eisenhower matrix: a simpler, slightly different approach that can be incorporated into kanban card prioritisation.

- Pareto principle: to identify high value cards to bring into the workflow.

- Deep work: could be a factor captured on kanban cards to help schedule required levels of focus time as required.

Kanban comes from two Japanese words meaning sign board, and is used by shop owners to display what services or products they offer.

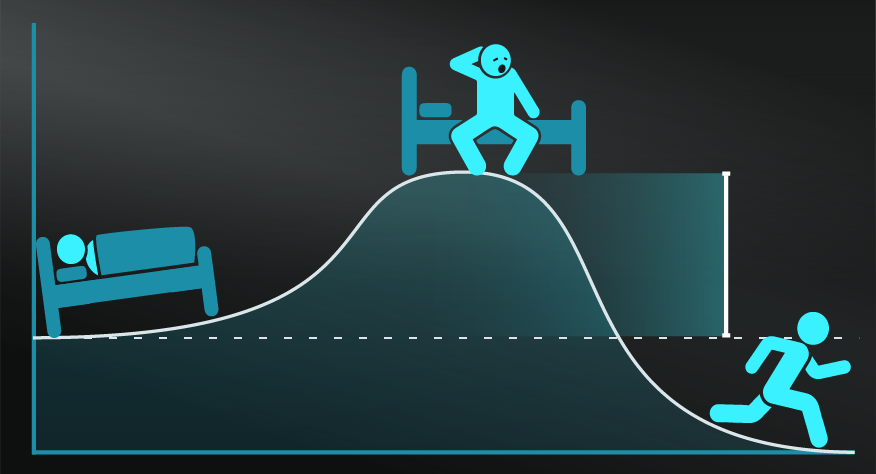

In the 1950s Taiichi Ohno, an engineer with Toyota, was considered to invent lean manufacturing and kanban. Inspired by noticing how a US supermarket stocked its shelves with a ‘just-in-time’ approach, filling them as they became empty, Ohno applied the same mental model in manufacturing. He created cards to represent production line demand within Toyota factories and developed the broader kanban approach to organise workflow, identify bottlenecks and deliver a just-in-time framework to manufacturing.

It wasn’t until the 2000s when project managers from other industries started to adopt the method. It found its biggest breakthrough by aligning with the formation of the Agile Manifesto and becoming a core approach within software development.

For a practical approach to kanban, view Atlassian’s overview here. Also see Taiichi Ohno’s classic text: Toyota Production System: Beyond large-scale production.

My Notes

My Notes

Oops, That’s Members’ Only!

Fortunately, it only costs US$5/month to Join ModelThinkers and access everything so that you can rapidly discover, learn, and apply the world’s most powerful ideas.

ModelThinkers membership at a glance:

“Yeah, we hate pop ups too. But we wanted to let you know that, with ModelThinkers, we’re making it easier for you to adapt, innovate and create value. We hope you’ll join us and the growing community of ModelThinkers today.”